- Coolant hole of Mold drilling with DeepTri-Drill

- Longer tool life with FINE BEAM in shaft drilling

- Spindle drilling time reduced with FINE BEAM

- Power steering shaft drilling with BTU drill head

- Wind power generator, main shaft drilling with Unidex

- High-speed train axle drilling with Unidex

- High quality surface finish with the HF drill

- Turbine Casing drilling with the DTS tooling

- Tube sheet drilling with the BTU drill head

Coolant hole of Mold drilling with DeepTri-Drill

DeepTri-Drill has improved productivity and drilling stability with double the feed rate and eliminated premature tool failures. No need for regrinding worn drills, reducing tool inventory and management.

| Component | Plastic mold |

| Material | SKD61 / X40CrMoV5-1 (45HRC) |

| Application | Gun drilling |

| Tool diameter | ø18.00 mm |

| Machine | Horizontal M/C |

| Coolant | Wet |

| Cutting speed | 62 m/min |

| Spindle speed | 0.04 mm/rev |

| Chip Breaker | NDJ |

| Grade | AH9130 |

Longer tool life with FINE BEAM in shaft drilling

Tool life is longer than competitive product by 1.7 times. Also hole straightness is improved by 80%.

| Component | Shaft |

| Material | Alloyed steel |

| Application | Solid drilling |

| Tool diameter | ø59.75 mm |

| Drilling depth | 1000 mm |

| Machine | BTA machine |

| Coolant | Oil based |

| Cutting speed | 56 m/min |

| Spindle speed | 0.16 mm/rev |

| Chip Breaker | G |

| Grade | UC2220 (NLX) |

Drilling time reduced with FINE BEAM in spindle drilling

Drilling time was reduced by half than existing tool. Hole straightness is also improved by 30%.

| Component | Spindle |

| Material | Alloyed steel |

| Application | Solid drilling |

| Tool diameter | ø32.2 mm |

| Drilling depth | 1500 mm |

| Machine | BTA machine |

| Coolant | Oil based |

| Cutting speed | 69 m/min |

| Spindle speed | 0.18 mm/rev |

| Chip Breaker | G |

| Grade | UC2220 (NLX) |

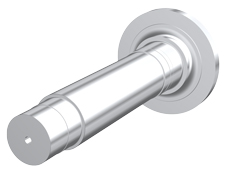

Power steering shaft drilling with BTU drill head

Drilling D12.6x500mm, reduced machining time significantly from 4.5 min. to 2 min. per workpiece with STS (BTA) drilling which replaced gundrilling. Also better accuracy was achieved.

| Material | Carbon steel |

| Tool diameter | ø12.6 mm |

| Drilling depth | 500 mm |

| Machine | BTA machine |

| Coolant | Oil based |

| Cutting speed | 90.6 m/min |

| Spindle speed | 0.12 mm/rev |

| Grade | 2122 (N3+ZAP) |

Wind power generator, main shaft drilling with Unidex

Unidex achieved straightness of 0.2mm/1,500mm in one pass solid drilling of high hardness steel.

| Material | Low alloyed steel |

| Tool diameter | ø155 mm |

| Drilling depth | 1,500 mm |

| Coolant | Oil based |

| Cutting speed | 49 m/min |

| Spindle speed | 0.12 mm/rev |

| Chip Breaker | G |

| Grade | UC2220 (NLX) |

High-speed train axle drilling with Unidex

Drilling D60X2600mm, Unidex achieved the required hole tolerance in one pass before honing. Also helped to reduce operation process, lowering overall machining time.

| Material | Carbon steel |

| Tool diameter | ø60 mm |

| Drilling depth | 2,600 mm |

| Coolant | Oil based |

| Cutting speed | 80 m/min |

| Spindle speed | 0.16 mm/rev |

| Chip Breaker | BR1 |

| Grade | UC1125 (DLXT) |

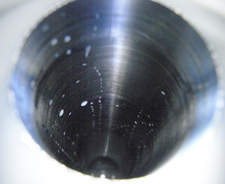

High quality surface finish with the HF drill

Burnishing effect improves surface finish. Possible to eliminate finishing process.

| Material | Carbon steel |

| Tool diameter | ø30 mm |

| Drilling depth | 200 mm |

| Machine | BT50 M/C |

| Coolant | Emulsion |

| Cutting speed | 100 m/min |

| Spindle speed | 0.1 mm/rev |

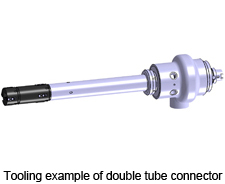

Turbine Casing drilling with the DTS tooling

The casings, huge components of power generators, require a large number of bolt holes which in the past demanded long machining time with high-speed steel drills and finish boring. Unitac's innovative DTS tooling has been able to dramatically reduce this machining time from 250 min. to 20 min.

| Component | Turbine casing |

| Material | Low alloyed steel |

| Application | Solid drilling |

| Tool diameter | ø118 mm |

| Machine | Horizontal boring and milling machine |

| Coolant | Oil based |

| Cutting speed | 110 m/min |

| Spindle speed | 0.17 mm/rev |

| Chip Breaker | G |

| Grade | UC2220 (NLX) |

Tube sheet drilling with the BTU drill head

In the past, when drilling 18,000 holes in a tube sheet, drills had to be replaced every 15 holes. But our tool life has improved to 25 holes, reducing drill usage from 1,200 to 720.

| Component | Tube sheet |

| Material | SA508 Gr.3 Cl.2 + Inconel 690 |

| Application | Solid drilling |

| Tool diameter | ø19.28 mm |

| Machine | BTA machine |

| Coolant | Oil based |

| Cutting speed | 90 m/min |

| Spindle speed | 0.16 mm/rev |

| Chip Breaker | BA |

| Grade | 1132 (UX2+ZAP) |